R series

Metallic ring joint gaskets are heavy duty High pressure gaskets largely used in Offshore petrochemical applications. They are precision-engineered components designed to be used in conjunction with Precision machined flanges. Our entire ring Joints are manufactured to ASME B16.20 and API 6A.

The gasket material is selected on a number of grounds primarily, chemical compatibility with media and hardness of the flange. The gasket material ideally needs to be roughly 30 Brinell less than the flange material to ensure sufficient deformation of the gasket without damaging the flange facing.

Common Material

|

Material availability & technical information from API & solid metal ring joints |

|||

|

Material |

Brinell Hardness |

Temperature ºC |

Identification |

|

Soft Iron |

90 |

-60 +500 |

D |

|

Low Carbon Steel |

120 |

-40 +500 |

S |

|

4%-6% Chrome ½% Mo |

130 |

-125 +500 |

F5 |

|

SS 304 |

160 |

-250 +500 |

S304 |

|

SS316 |

160 |

-110 +550 |

S316 |

|

SS 321 |

160 |

-250 +550 |

S321 |

|

SS 347 |

160 |

-250 +550 |

S347 |

|

SS 410 |

170 |

-20 +500 |

S410 |

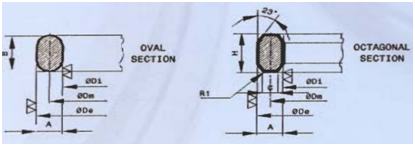

Metal Ring Joint gasket Type R

The R metal ring joint gasket are manufactured according to ASME B 16.20: 1998 and API 6A. The type R oval configuration was the original design and was followed by the type R octagonal which offered more specific contact areas.

Related Products

Product message

subscribe to our newsletter